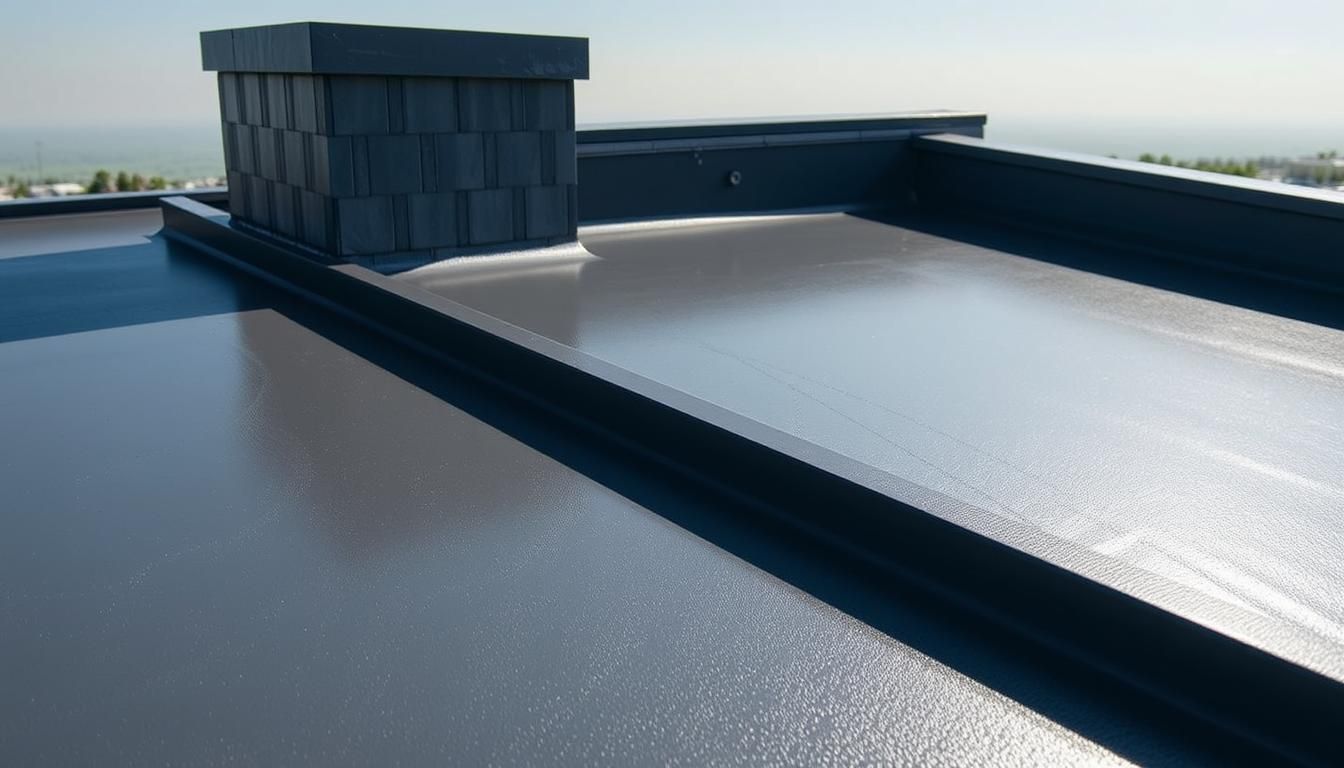

At Archibeque Roofing, we know everyone has different needs. We aim to go beyond what you expect! Our elastomeric roof coating solutions offer a strong shield for your roof.

Elastomeric roof coatings are tough and keep your roof safe from leaks and damage. They stretch and adjust with temperature changes. This makes them perfect for your roofing needs.

Looking for a dependable roofing fix? Call Archibeque Roofing today at (720)375-5601. Our team is ready to give you the best service and make sure you're happy.

Key Takeaways

- Elastomeric roof coatings provide a durable layer of protection.

- They are highly flexible and can expand and contract with temperature changes.

- Archibeque Roofing offers customized solutions to meet your roofing needs.

- Contact Archibeque Roofing at (720)375-5601 for a reliable roofing solution.

- Our team is committed to exceeding your expectations.

What is Elastomeric Roof Coating?

Understanding elastomeric roof coating is key for homeowners looking for lasting roofing solutions. At Archibeque Roofing, we aim to give top-notch customer service. This includes teaching our clients about elastomeric roof coatings' benefits and features.

Definition and Basic Properties

An elastomeric roof coating is a liquid paint used in commercial roofing. It forms a membrane over an existing roof, offering several advantages. Its main trait is elasticity, allowing it to stretch and contract with the roof due to temperature changes.

This elasticity sets elastomeric coatings apart from other roofing materials. Elastomeric coatings are also known for their waterproofing. They protect the roof from leaks and water damage.

History and Development of Elastomeric Coatings

The history of elastomeric coatings began in the mid-20th century. They were first used as a roofing solution. Since then, these coatings have seen significant improvements.

Advances in technology have led to better formulations. Today, elastomeric coatings are known for extending roof life, reducing energy costs, and being sustainable. The history of elastomeric coatings is a tale of ongoing innovation, driven by the quest for better roofing systems.

How Elastomeric Roof Coatings Work

It's important to understand how elastomeric roof coatings work. They are made from advanced polymers. These polymers create an elastomeric membrane. This membrane makes roofs waterproof and weatherproof.

The Science Behind Elastomeric Materials

Elastomeric materials are flexible and durable. They are often made from acrylic, silicone, or polyurethane. These materials can stretch and go back to their original shape without losing strength.

This flexibility is key for roofs. It lets them adjust to temperature changes without damage.

Elasticity and Waterproofing Properties

The elasticity of elastomeric coatings offers many benefits. Here are a few:

- Seamless protection against leaks

- Ability to bridge small cracks and gaps in the roof surface

- Enhanced durability and resistance to weathering

These features make elastomeric roof coatings a great choice. They protect roofs from damage and extend their life. By creating a continuous, waterproof barrier, they prevent water intrusion and lower repair costs.

Types of Elastomeric Roof Coatings

Elastomeric roof coatings come in different types, each for a specific use. The right choice depends on the climate, roof type, and how long you want it to last.

Acrylic Elastomeric Coatings

Acrylic elastomeric coatings are loved for their flexibility and durability. They're water-based, making them simple to apply and clean up. These coatings work well on many roofing materials, like metal, concrete, and asphalt.

Silicone Elastomeric Coatings

Silicone elastomeric coatings are top-notch for waterproofing. They stand up well to UV rays and extreme temperatures. These coatings are perfect for roofs that get a lot of rain or sun.

Polyurethane Elastomeric Coatings

Polyurethane elastomeric coatings have high tensile strength and resist wear and tear. They're great for roofs that get a lot of foot traffic or are easily damaged by debris.

Butyl and SEBS Coatings

Butyl and SEBS (Styrene-Ethylene-Butylene-Styrene) coatings are less common but have special benefits. Butyl coatings stick well, while SEBS coatings are very flexible and weather-resistant.

In summary, picking the right elastomeric roof coating depends on the roof's needs. This includes the material, weather exposure, and how long you want it to last. Knowing what each type offers helps homeowners and building managers make the best choice for their roofs.

Benefits of Elastomeric Roof Coating

Elastomeric roof coatings bring many benefits to both homeowners and businesses. They are more than just a protective layer. They solve many roofing problems.

Extended Roof Lifespan

One big plus of elastomeric roof coatings is they make roofs last longer. They shield roofs from the weather, adding years to their life. This means you won't have to replace your roof as often, saving you money.

Energy Efficiency and Cost Savings

These coatings also help save energy. They reflect sunlight, keeping your roof cooler. This can lower your cooling costs in the summer. It's a smart choice for saving money over time.

Weather Resistance in Denver's Climate

Denver's weather is perfect for elastomeric roof coatings. They stand up well to the sun, low humidity, and moderate temperatures. Their flexibility means they stretch and shrink with the roof, keeping it sealed.

Seamless Protection Against Leaks

Elastomeric coatings cover the roof without gaps, stopping leaks. This is key in avoiding expensive water damage. Their seamless design means water can't find a way in.

Environmental Benefits

Finally, these coatings are good for the planet. They help roofs last longer, cutting down on waste. Plus, many are made to be eco-friendly, making them even better for the environment.

Elastomeric Roof Coating vs. Silicone: A Comprehensive Comparison

Both elastomeric roof coatings and silicone coatings have their own benefits. It's important to know how they differ.

Durability Differences

Elastomeric roof coatings are very elastic and can handle extreme temperatures well. They are very durable. Silicone coatings, however, are great at resisting UV rays and are flexible. Here's a table comparing their durability:

| Coating Type | Durability Features |

|---|---|

| Elastomeric | Elasticity, Temperature Resistance |

| Silicone | UV Resistance, Flexibility |

Cost Comparison

The cost of these coatings can vary. Elastomeric coatings are often cheaper because they last longer. Silicone coatings might cost more at first but save money in the long run due to less maintenance.

Application Considerations

Elastomeric coatings are easy to apply and work on many surfaces. Silicone coatings need a clean, dry surface for best adhesion. Knowing these application details is crucial for a successful roof job.

Performance in Colorado's Weather Conditions

Colorado's weather is tough on roofs, with lots of sun and big temperature changes. Elastomeric coatings do well here because they stretch and reflect the sun. Silicone coatings also do great, protecting against UV rays and staying flexible.

Elastomeric Sealant vs. Silicone Sealant for Roofing

It's important to know the differences between elastomeric and silicone sealants for roofing. Each has its own strengths and uses. The right choice depends on several factors.

Chemical Composition Differences

Elastomeric sealants are made from materials that stretch and return to shape, like acrylic or polyurethane. Silicone sealants are known for their flexibility and waterproofing. Their chemical makeup impacts how well they work and last.

Performance in Various Weather Conditions

Elastomeric sealants work well in many temperatures and weather. They handle UV exposure and extreme temperatures well. Silicone sealants also resist weather, especially in high-temperature conditions. Knowing how each performs is key to picking the right sealant for a roof.

Best Applications for Each in Roofing Projects

Choosing between elastomeric and silicone sealants depends on the roofing project's needs. Elastomeric sealants are great for their elasticity and durability. Silicone sealants are best for waterproofing. Here are some uses:

- Elastomeric sealants for projects needing flexibility and weather resistance.

- Silicone sealants for high-temperature applications.

Roofing experts can make better choices by knowing each sealant's strengths and weaknesses. This ensures the roof lasts long and stays strong.

Understanding Elastomeric Membrane Roofing Systems

Elastomeric membrane roofing offers a flexible yet strong defense against weather. It keeps buildings safe from rain, snow, and extreme temperatures.

What is an Elastomeric Membrane?

An elastomeric membrane is made from materials that stretch like rubber. These membranes stretch and shrink with the building's temperature changes.

Key characteristics of elastomeric membranes include:

- High elasticity

- Waterproofing capabilities

- Resistance to UV degradation

- Flexibility in various temperatures

Types of Elastomeric Membranes

There are many types of elastomeric membranes, each with its own benefits.

| Type | Description | Advantages |

|---|---|---|

| EPDM (Ethylene Propylene Diene Monomer) | A synthetic rubber membrane known for its durability and resistance to weathering. | High resistance to ozone and UV, flexible in cold temperatures |

| PVC (Polyvinyl Chloride) | A plasticized PVC membrane that is flexible and resistant to chemicals and fire. | High chemical resistance, weldable seams for watertight seal |

| TPO (Thermoplastic Polyolefin) | A single-ply roofing membrane that is known for its energy efficiency and resistance to UV radiation. | Energy-efficient, resistant to UV and chemical degradation |

Installation Process and Requirements

Installing elastomeric membrane roofing needs careful planning and execution. It involves preparing the roof, applying the membrane, and sealing seams.

The installation process depends on the membrane type and local building codes. Always consult a professional roofing contractor for correct installation.

Elastomer vs. Plastic: Material Science for Roofing

Elastomers and plastics are two different materials used in roofing. Each has its own benefits and characteristics. Knowing the differences is key to making smart choices in roofing.

Material Properties and Behavior

Elastomers are very elastic and can stretch a lot without breaking. This makes them great for roofs that need to bend. Plastics, however, are stiffer and less elastic than elastomers.

Key Material Properties:

| Property | Elastomers | Plastics |

|---|---|---|

| Elasticity | High | Low to Moderate |

| Durability | High | Variable |

| Chemical Resistance | Good | Variable |

Applications in the Roofing Industry

Elastomers are popular in roofing because they're waterproof and flexible. They're often used as coatings or membranes to keep roofs dry. Plastics, though less flexible, are used in roofing membranes and profiles too.

Longevity and Performance Differences

The life and performance of elastomers and plastics in roofing depend on their properties and the weather. Elastomers usually last longer and perform better in harsh weather because of their elasticity and waterproofing.

In short, when picking between elastomers and plastics for roofing, think about their properties, uses, and how they perform. This will help ensure the best results for your roofing project.

Professional Application Process for Elastomeric Roof Coating

Getting elastomeric roof coating to work right takes a few key steps. These include getting the surface ready, applying the coating, and letting it cure. Each step is important for the coating to last and perform well.

Surface Preparation and Inspection

Before you start with elastomeric roof coating, clean and check the roof for damage or dirt. This is key to make sure the coating sticks well and doesn't leak. The roof should be clean of dirt, oil, and other stuff that could mess up the coating's stickiness.

Application Techniques and Tools

There are different ways to apply elastomeric roof coating, like rollers, sprayers, or brushes. The right tool makes sure the coating goes on evenly and right. Make sure to apply the coating the right thickness for the best waterproofing and stretchiness.

Curing Process

After you put on the elastomeric roof coating, it needs time to dry. This drying time can change based on the weather. Always follow the maker's instructions for drying to get the best out of your coating.

Maintenance and Reapplication Guidelines

To keep your elastomeric roof coating in top shape, regular checks and cleanings are a must. You might need to put on more coating every 10 to 15 years. This depends on the coating's quality and how the weather is.

Archibeque Roofing: Denver's Elastomeric Coating Experts

At Archibeque Roofing, we focus on top-quality elastomeric roof coating services for Denver homeowners. We're known for our excellence and are a trusted name in Denver, CO.

Our Approach to Elastomeric Roof Coating

Our team at Archibeque Roofing is very careful with elastomeric roof coating. We pay close attention to every detail. We also tailor our solutions to fit Denver's unique climate and each roof's needs.

Why Denver Homeowners Choose Archibeque Roofing

Denver residents choose Archibeque Roofing for elastomeric roof coating because we care about our customers. We're known for our quality work and making sure our clients get a durable, energy-saving roof.

Our Elastomeric Coating Process and Guarantee

Our elastomeric coating process includes careful preparation, precise application, and strict quality checks. We back our work with a solid guarantee. This gives our clients peace of mind and protects their investment.

At Archibeque Roofing, we aim to provide outstanding service and meet our customers' high expectations. Choosing us for your elastomeric roof coating means you're in safe hands.

Conclusion: Making the Right Choice for Your Roof

Choosing the right roofing material is key to a long-lasting roof. Elastomeric roof coating is a great choice. It extends roof life, saves energy, and withstands weather.

When picking an elastomeric roof coating, think about durability, cost, and how it's applied. Knowing the differences between acrylic, silicone, and polyurethane coatings helps you make a smart choice.

Investing in a top-notch elastomeric roof coating and hiring pros like Archibeque Roofing in Denver is wise. It keeps your roof safe from the elements and makes it last longer and use less energy.

Frequently Asked Questions About ELASOMERIC Roof Coatings

What is elastomeric roof coating?

Elastomeric roof coating is a protective layer for roofs. It keeps them safe from weather damage and leaks. It stretches and moves with the roof as it changes size.

How does elastomeric roof coating work?

It creates a waterproof layer on the roof. This layer fills in cracks and stops water from getting in. It also reflects sunlight to keep the roof cool.

What are the benefits of using elastomeric roof coating?

It makes roofs last longer and saves energy. It also protects against weather and is good for the environment. Plus, it can lower your energy bills by keeping the roof cool.

What is the difference between elastomeric roof coating and silicone coating?

Elastomeric coatings are more flexible and stretch with the roof. Silicone coatings are stiffer and might crack more easily.

What is elastomeric membrane roofing?

It's a roofing system with a flexible, waterproof membrane. It's great for flat or low-sloping roofs.

How is elastomeric roof coating applied?

It's applied with a sprayer or roller. The roof must be clean and ready before applying. After, it cures and is checked again.

What is the difference between elastomer and plastic?

Elastomers are flexible and elastic. Plastics are rigid and might crack more.

How long does elastomeric roof coating last?

Its lifespan varies based on quality, preparation, and environment. It can last 10 to 20 years or more.

Can elastomeric roof coating be used on any type of roof?

It works on many roofs, like flat and metal ones. But, it's not for all roofs, especially damaged ones.

Is elastomeric roof coating environmentally friendly?

Yes, it's eco-friendly. It saves energy and extends roof life, reducing waste and replacements.